PVC WELDING

PVC (polyvinyl chloride) foil is welded using high frequency. A technique that has been known since the mid-1950s. We have modern machinery and long experience with welding of PVC foil.

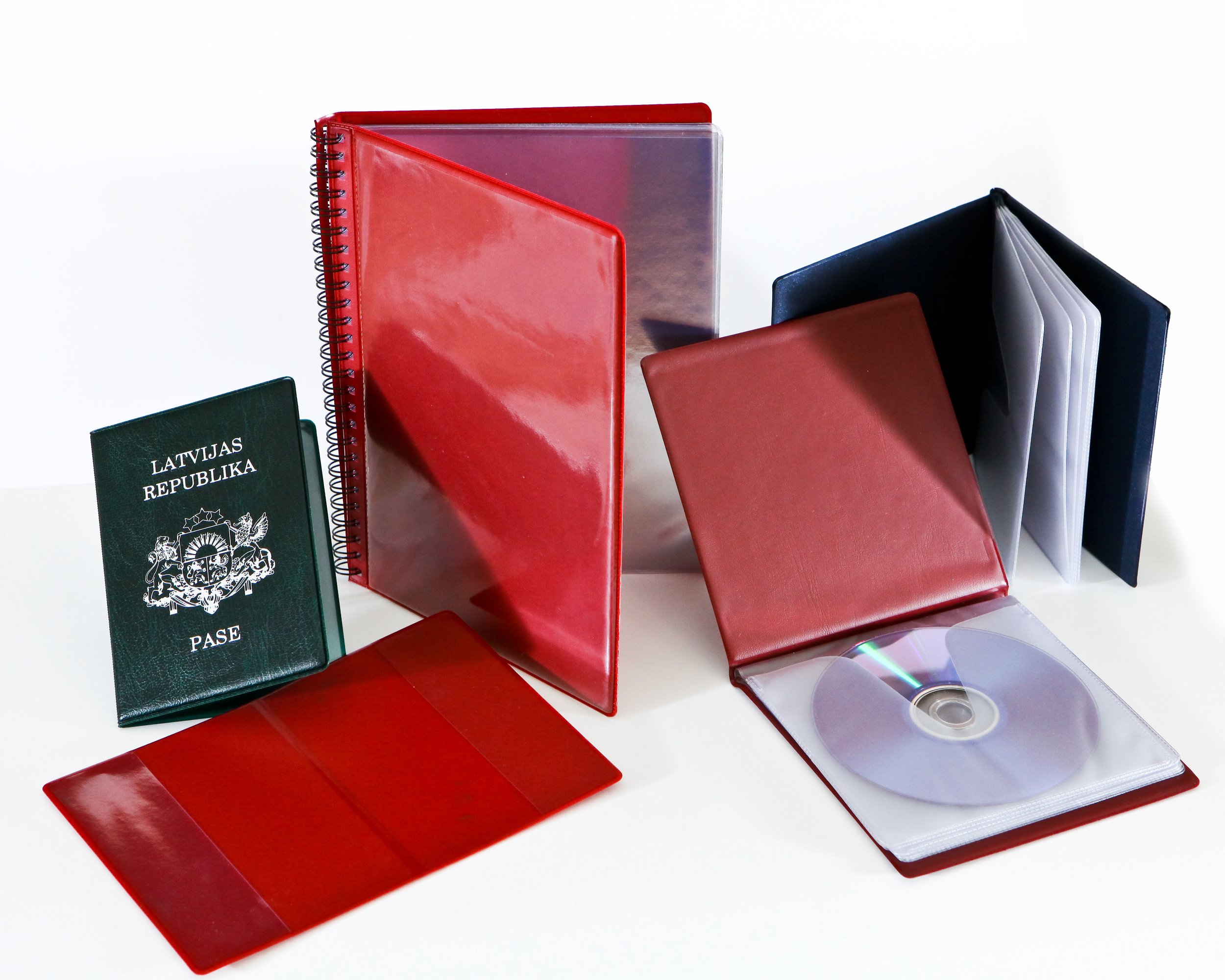

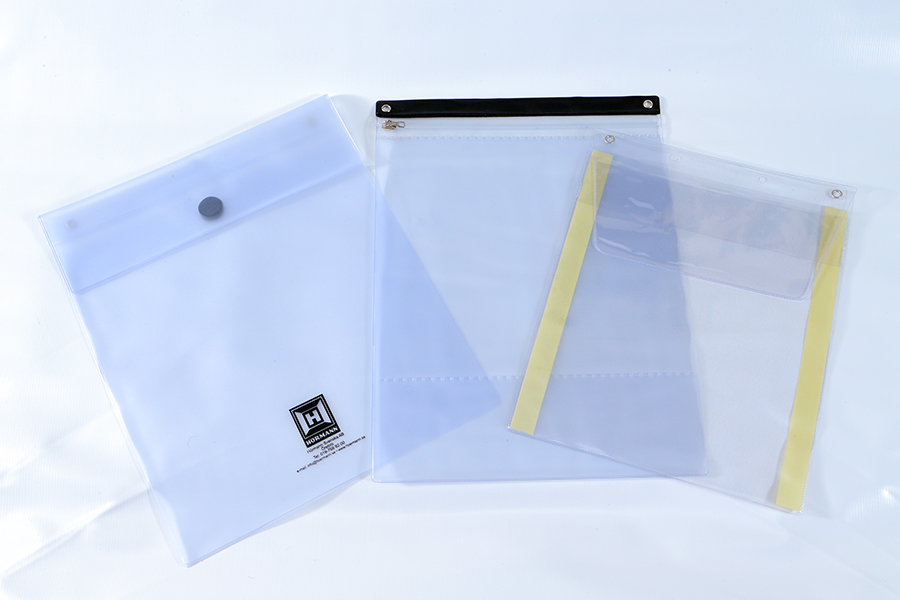

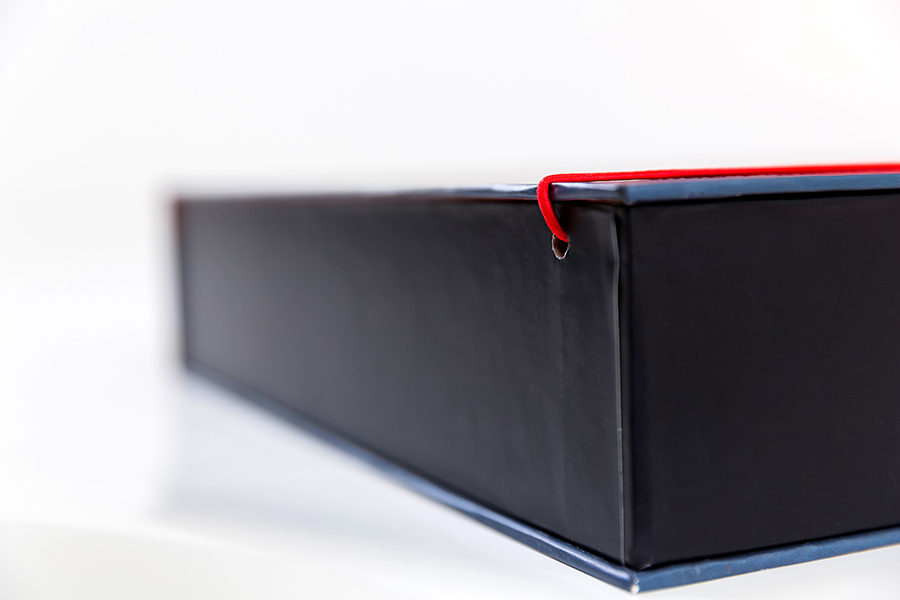

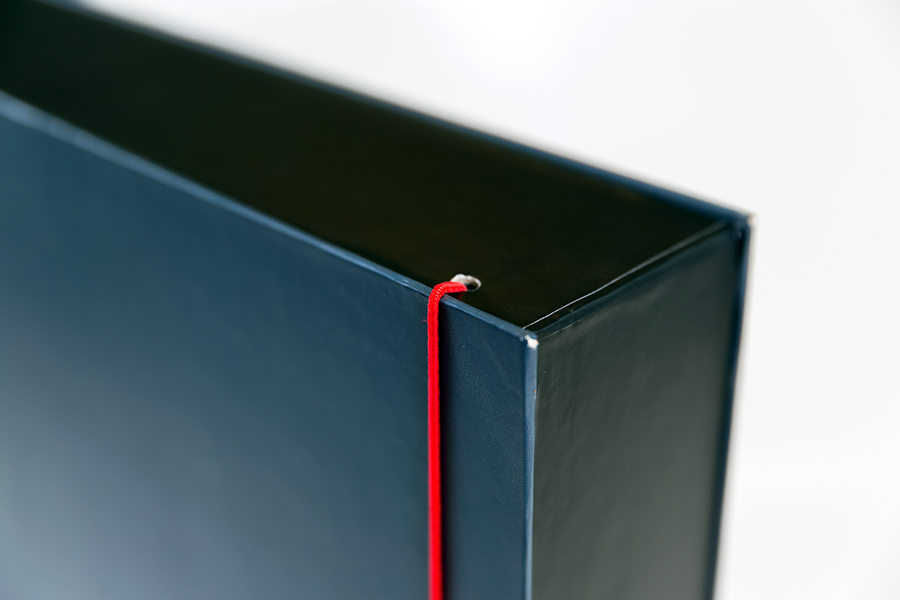

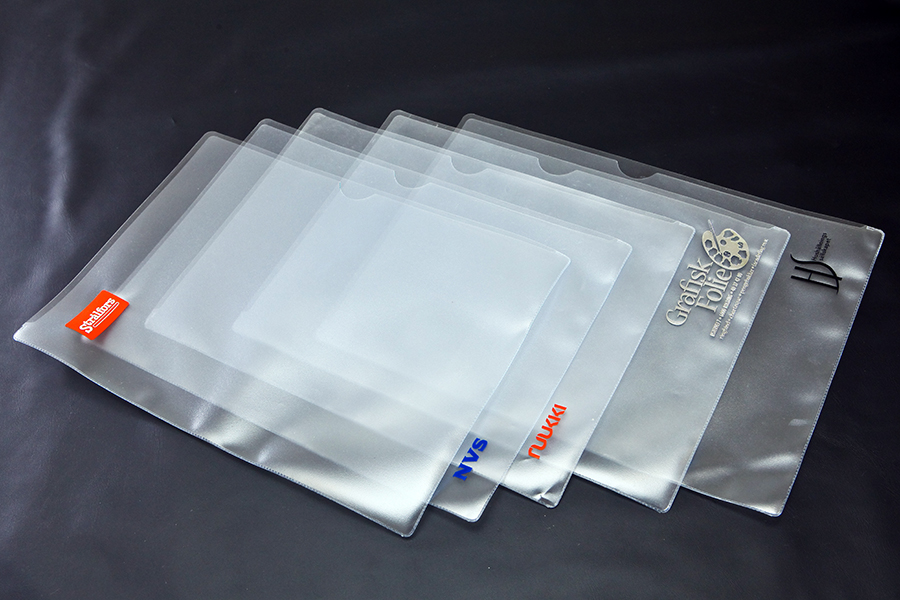

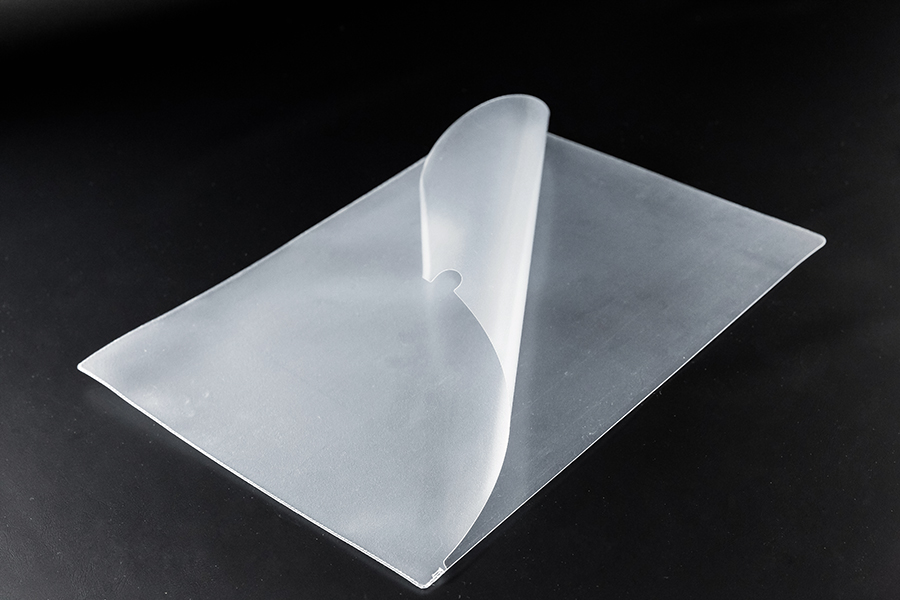

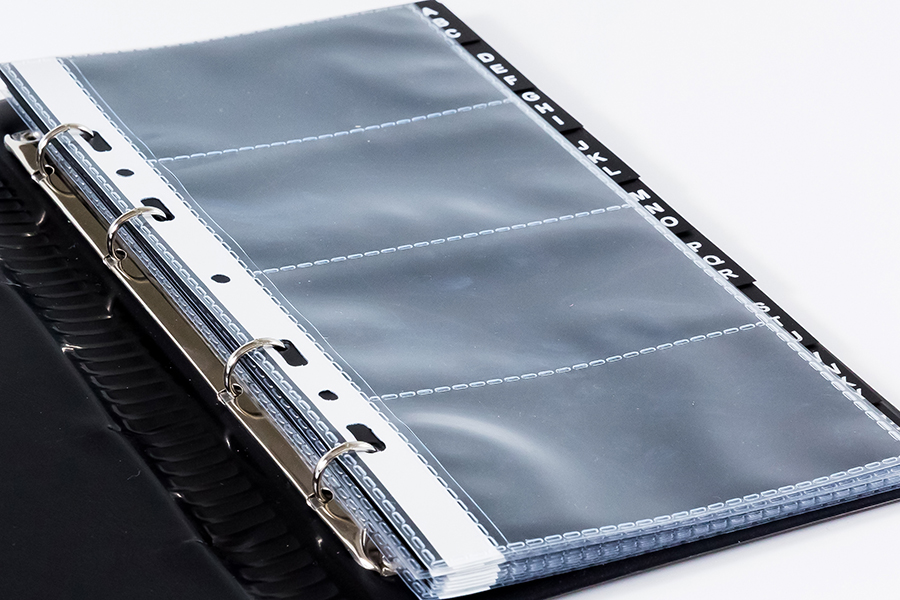

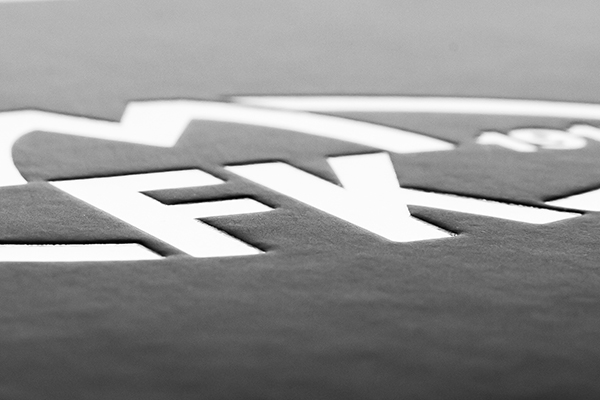

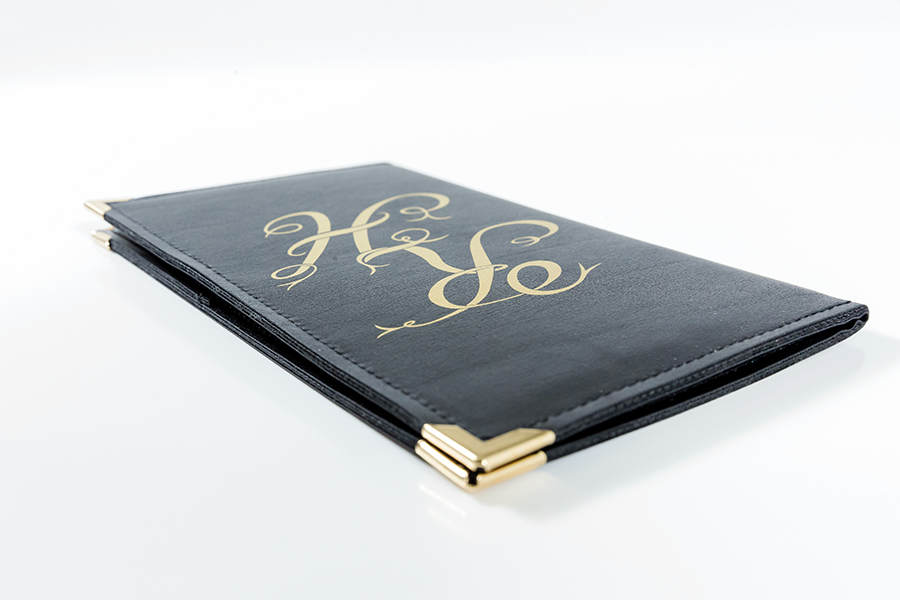

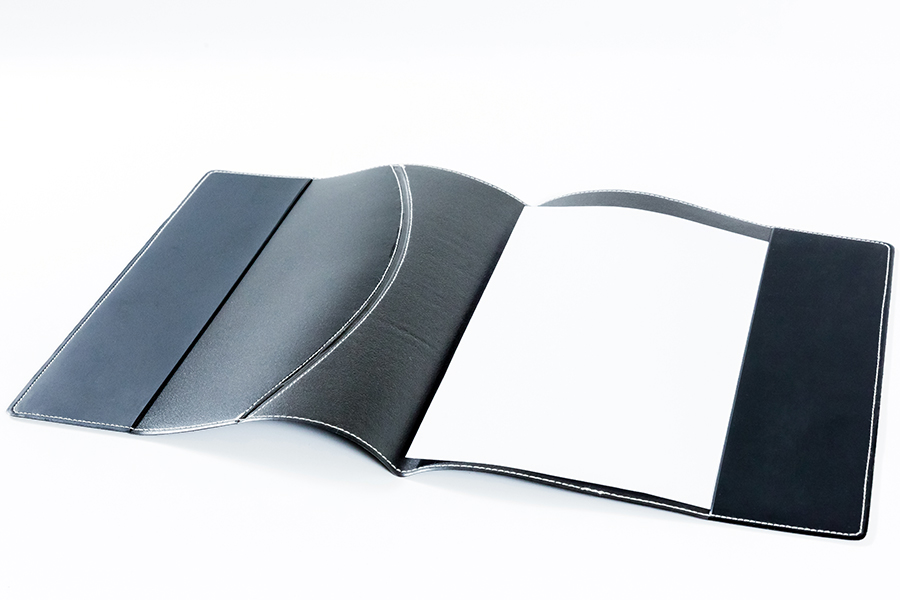

PVC foil is easy to control and create fine products such as binders, pockets, sleeves, covers and packaging to name a few.

PVC is the plastic type that is most thoroughly explored. PVC uses far less non-renewable oil resources than other thermoplastics. PVC plastic is known as an environmentally friendly material that affects the environment less than alternatives.